PROSTHETICS

This video shows a segment of the making process for a custom socket. The residual limb is layered with 2 sheets of woven NSP fibers,10 Flexastretch stocking nets and a graphic layer. ER resin is then poured into it to create a lightweight, rigid and durable composite. You can see the finished product on the right, it has a polyethylene inner liner built into the socket for comfort.

This is a BOA RevoFit carbon fiber socket. The cables running through the carbon fiber matrix allows for the socket to have an adjustable fit.

Below are carbon fiber sockets with graphics laminated into the device. Usually the graphics are from a cotton T shirt that we custom shape to the leg.

This mobile ankle has an air pump integrated into it to help keep the prosthetic attached to the user. An air tight valve is attached to the prosthetic and tubing runs down to connect both systems.

This is a running blade that needed to be modified for a Spartan Race (5K obstacle course). I widened the contact surface, added firm foam to the bottom, and wrapped Vibram outsole around the tip for better traction.

ORTHOTICS & MODIFICATIONS

This medical device is called a Crow Boot and it is made for patients with a disease called Charcot. The outer shell is made from polypropylene and the inside is lined with foam.

This solid ankle foot orthosis (SAFO) is to help patients not flex their foot when walking. This specific device is made with a front shell to add better stability and a more snug fit.

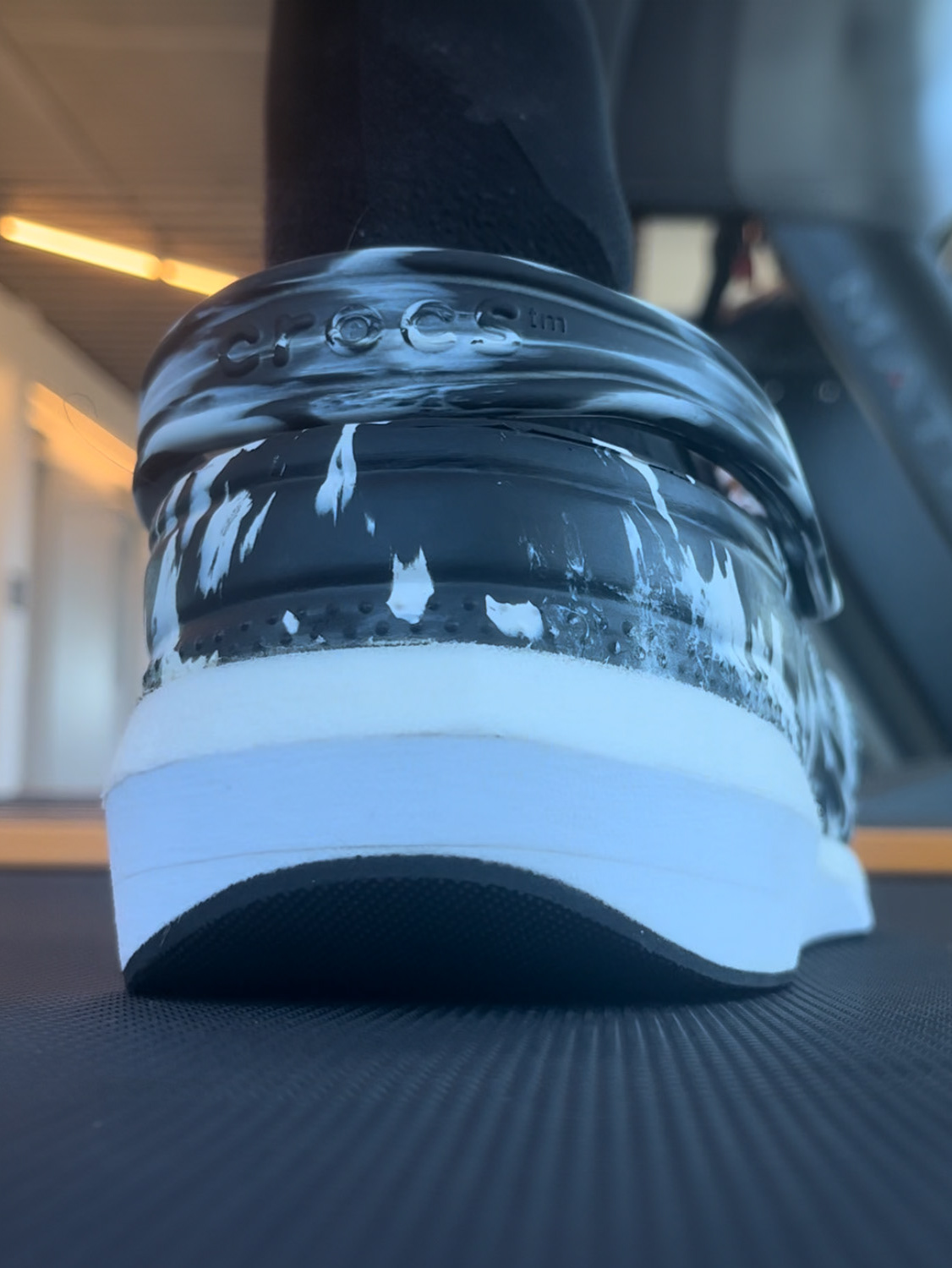

The goal of this shoe modification was to add a lift in the shoe while also keeping the same tread pattern. I used heat and acetone to peel the tread off and carefully lined it up with the new midsole.

This is another shoe lift but the immensity of the lift created an extremely heavy shoe. My method of drilling holes through each layer seemed to help create a lighter shoe overall.

CUSTOM CAD INSERT

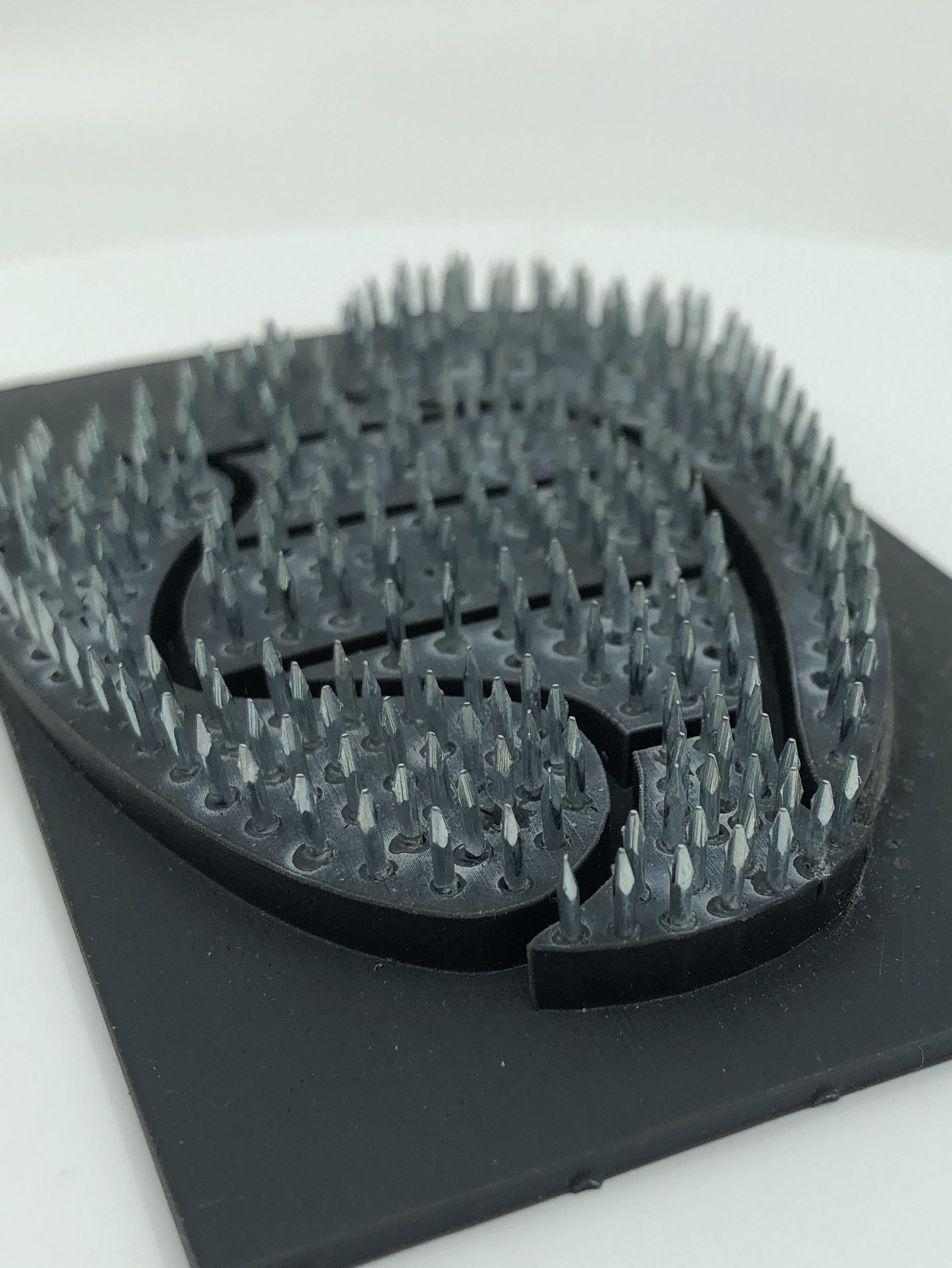

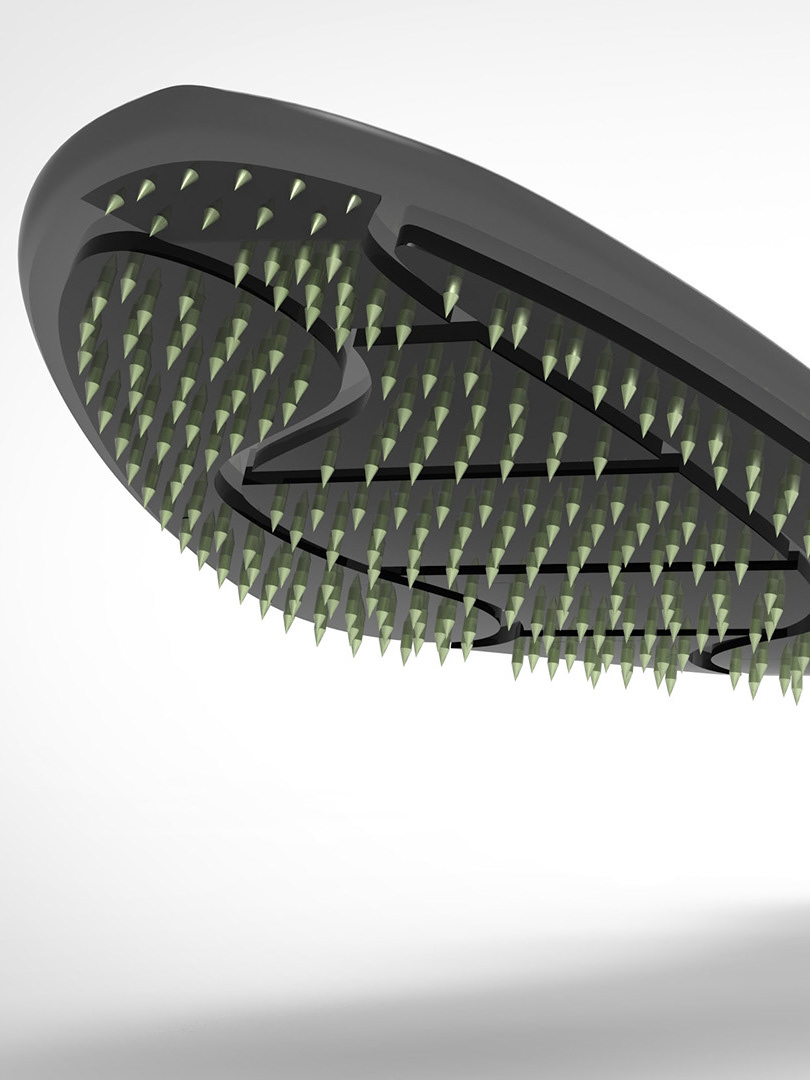

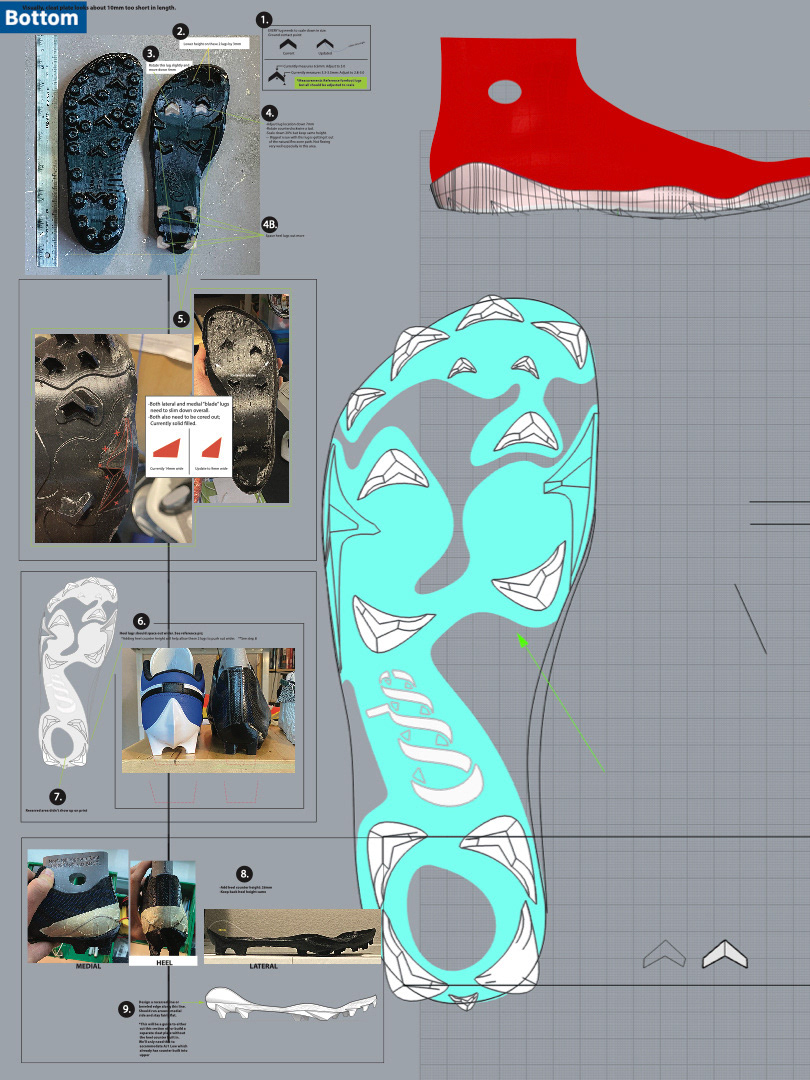

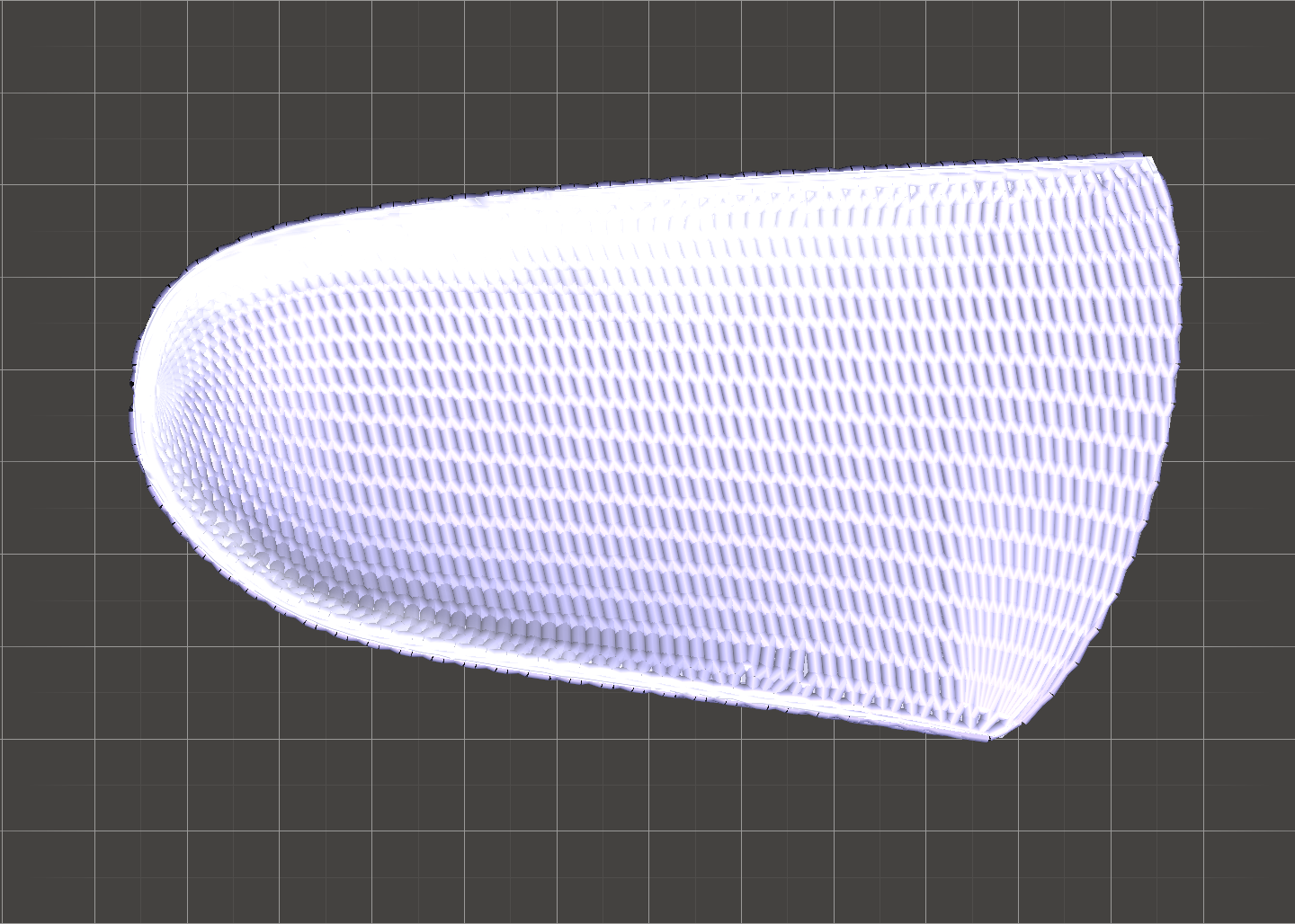

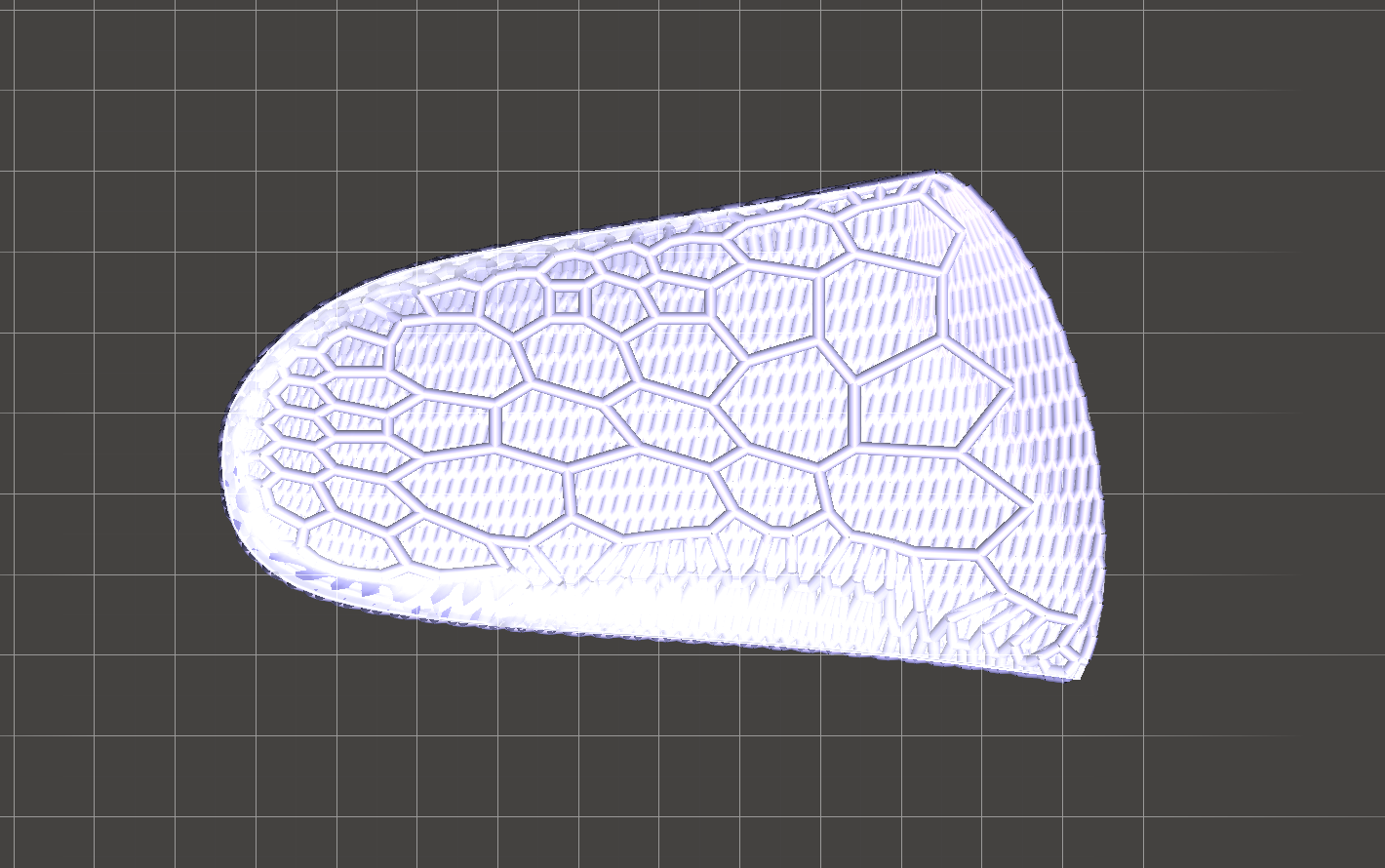

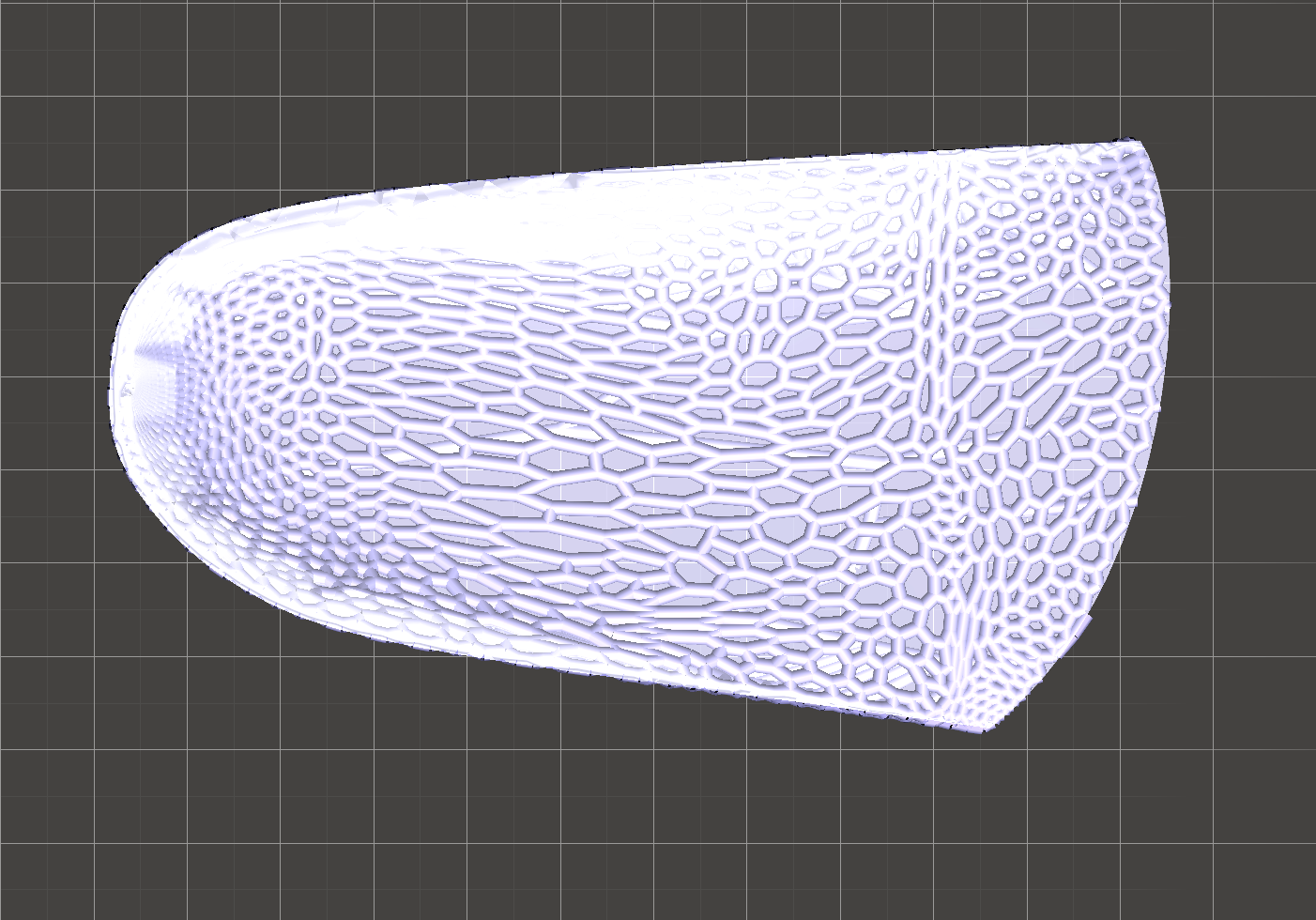

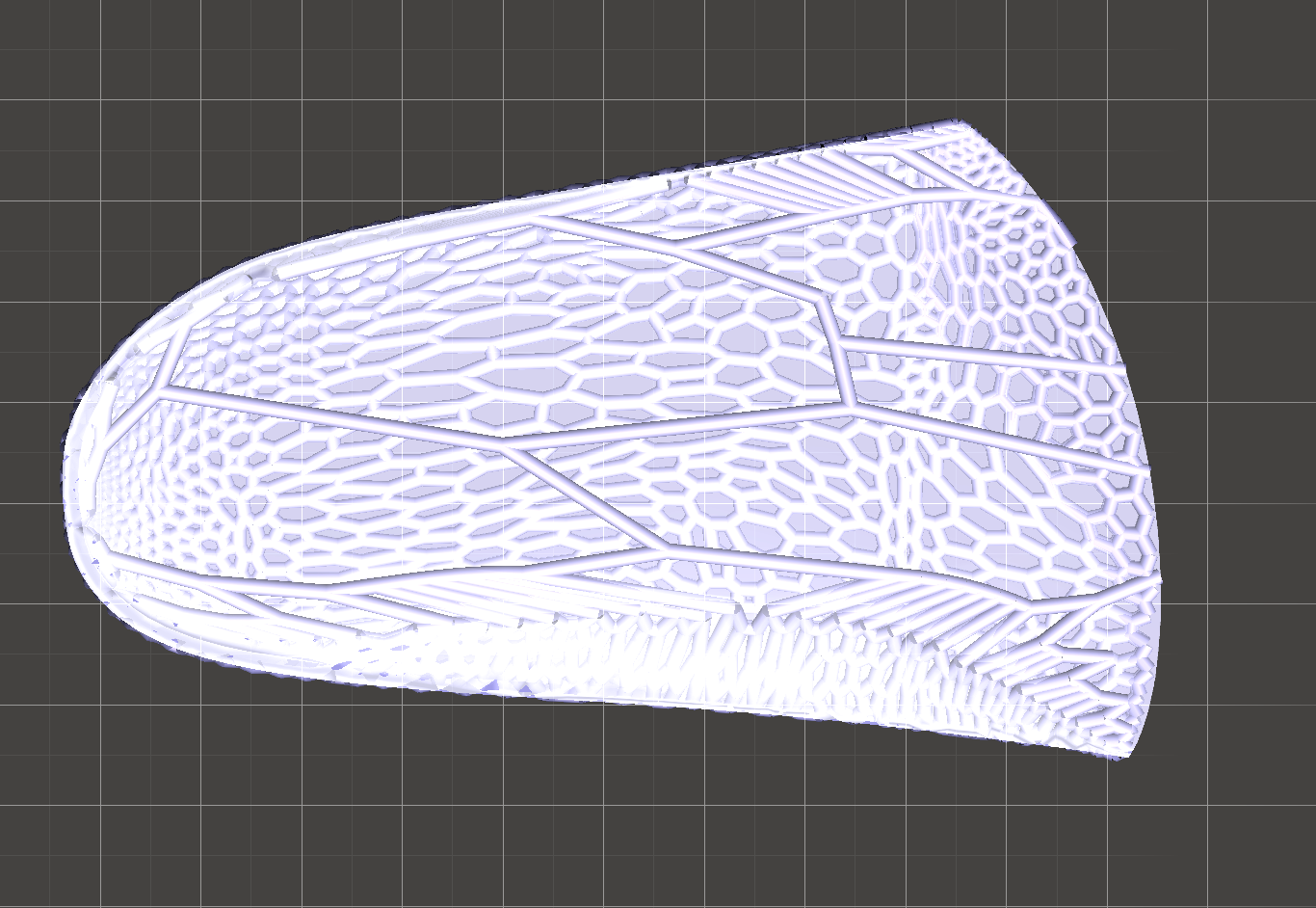

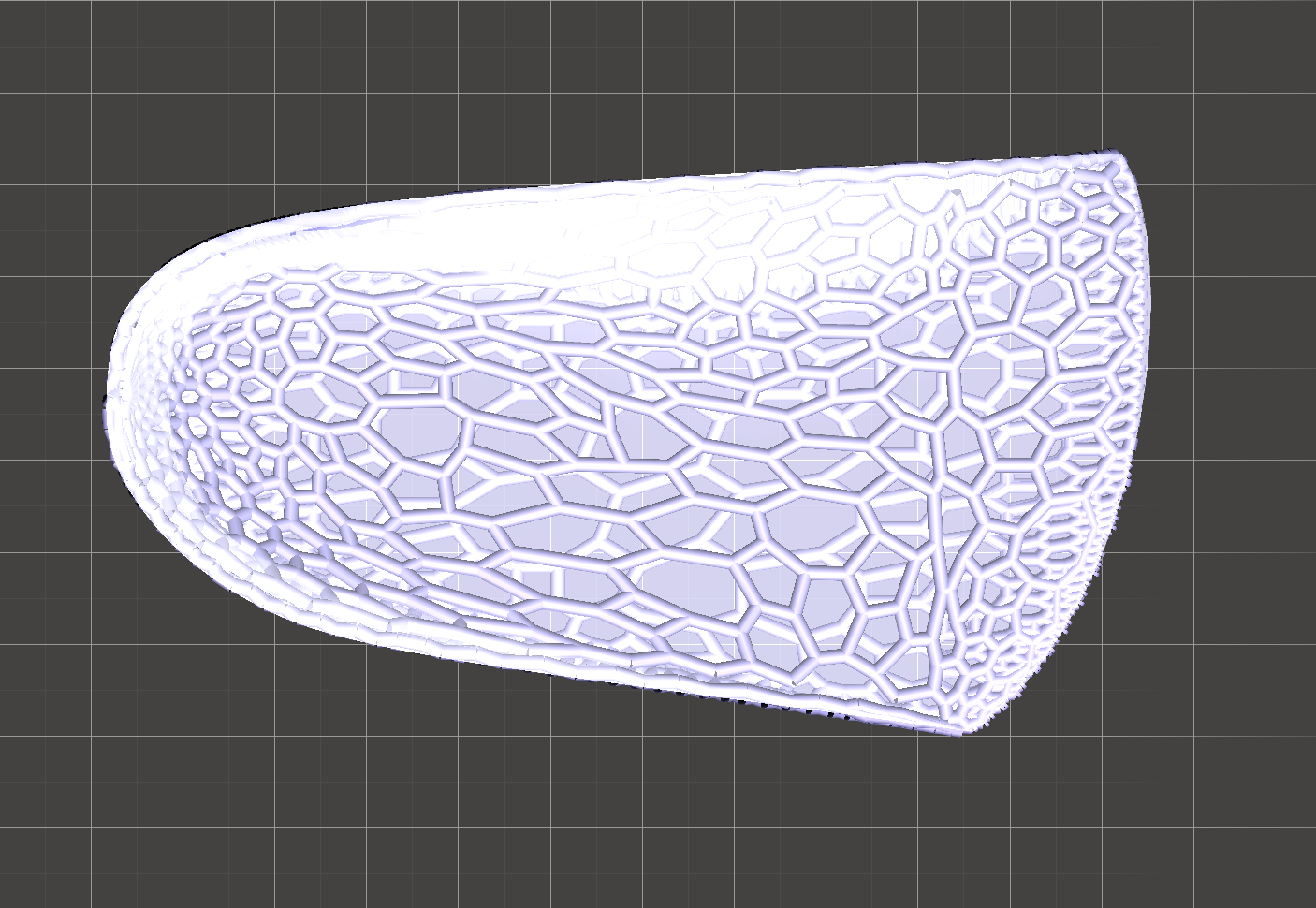

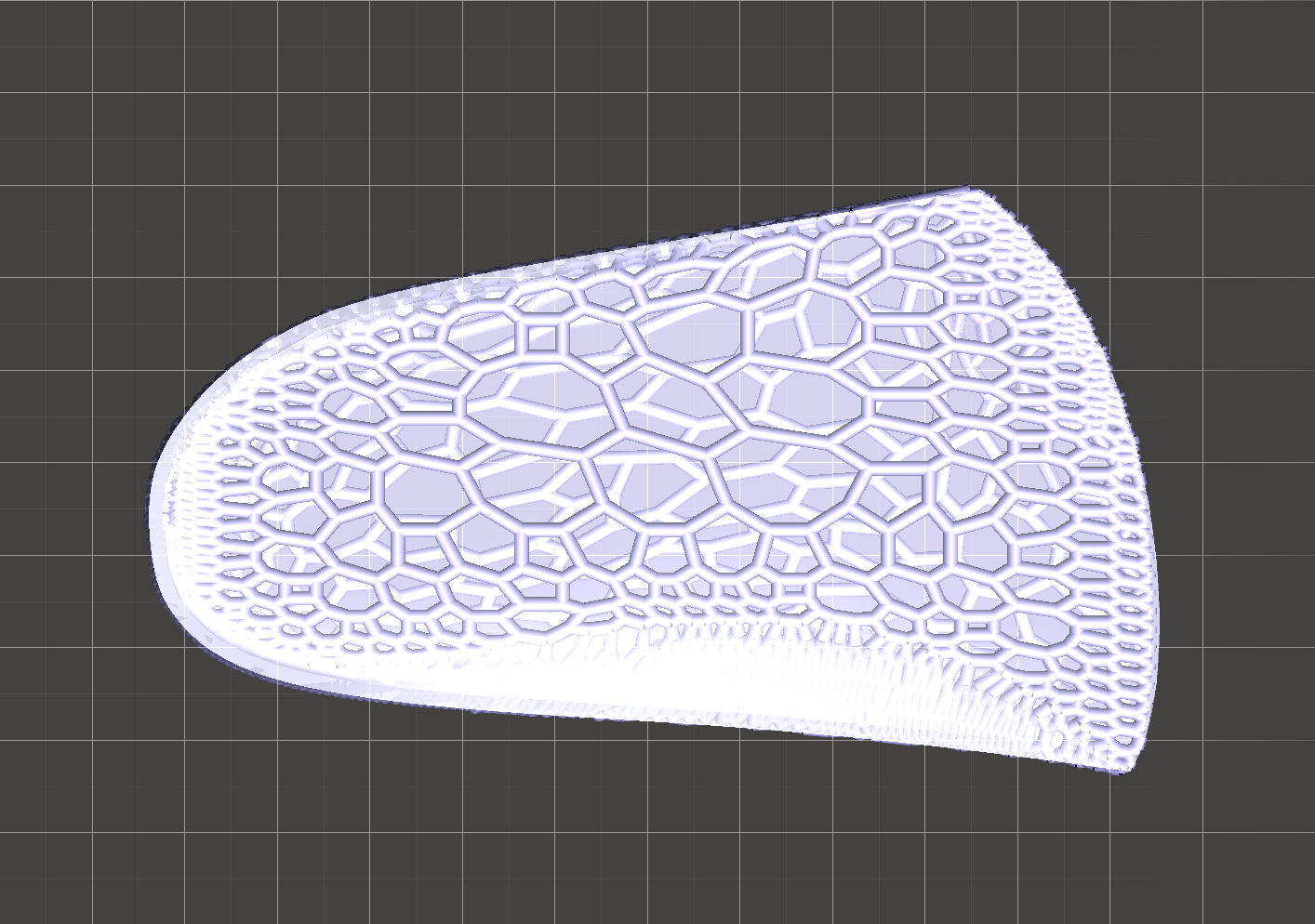

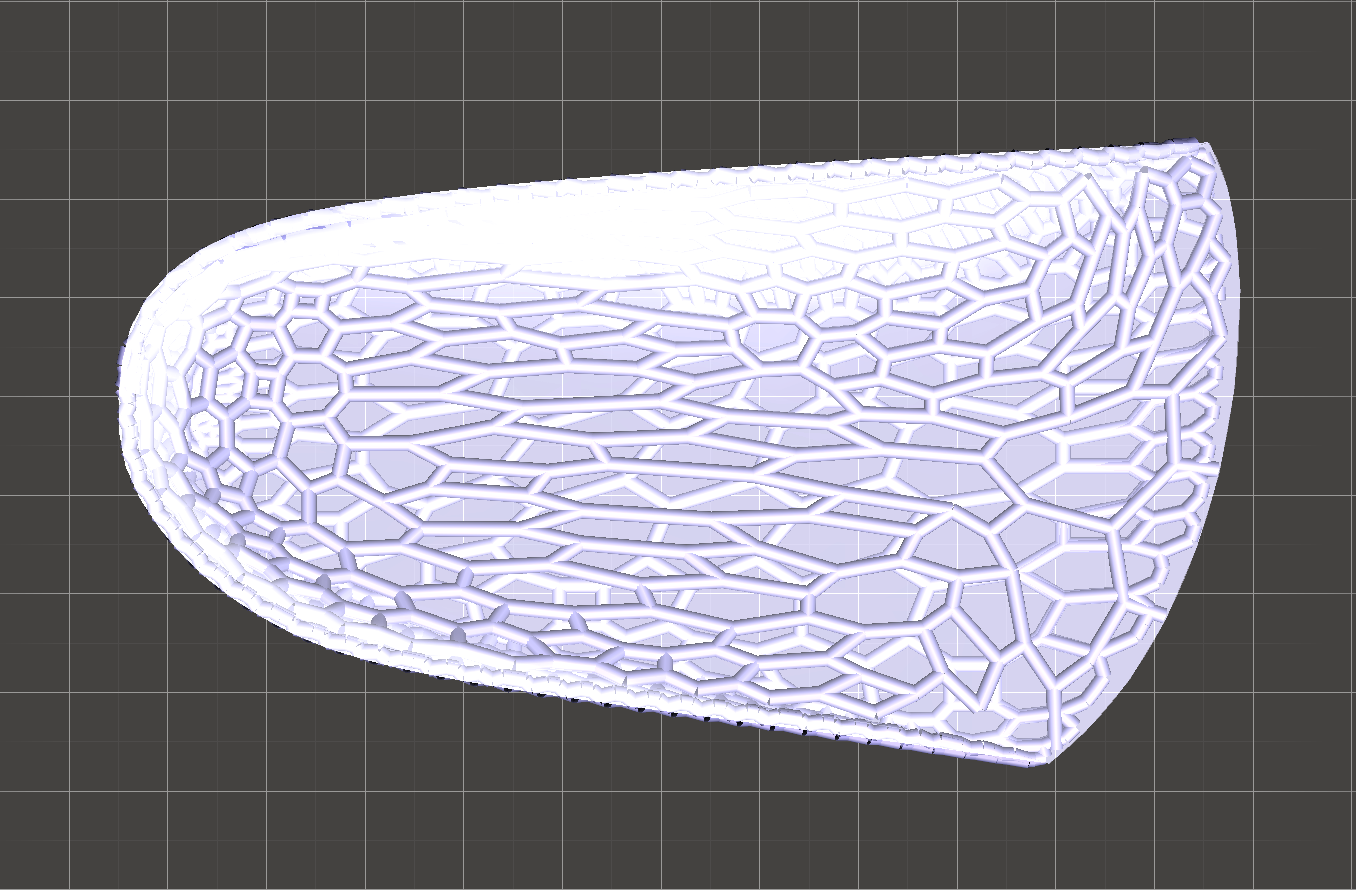

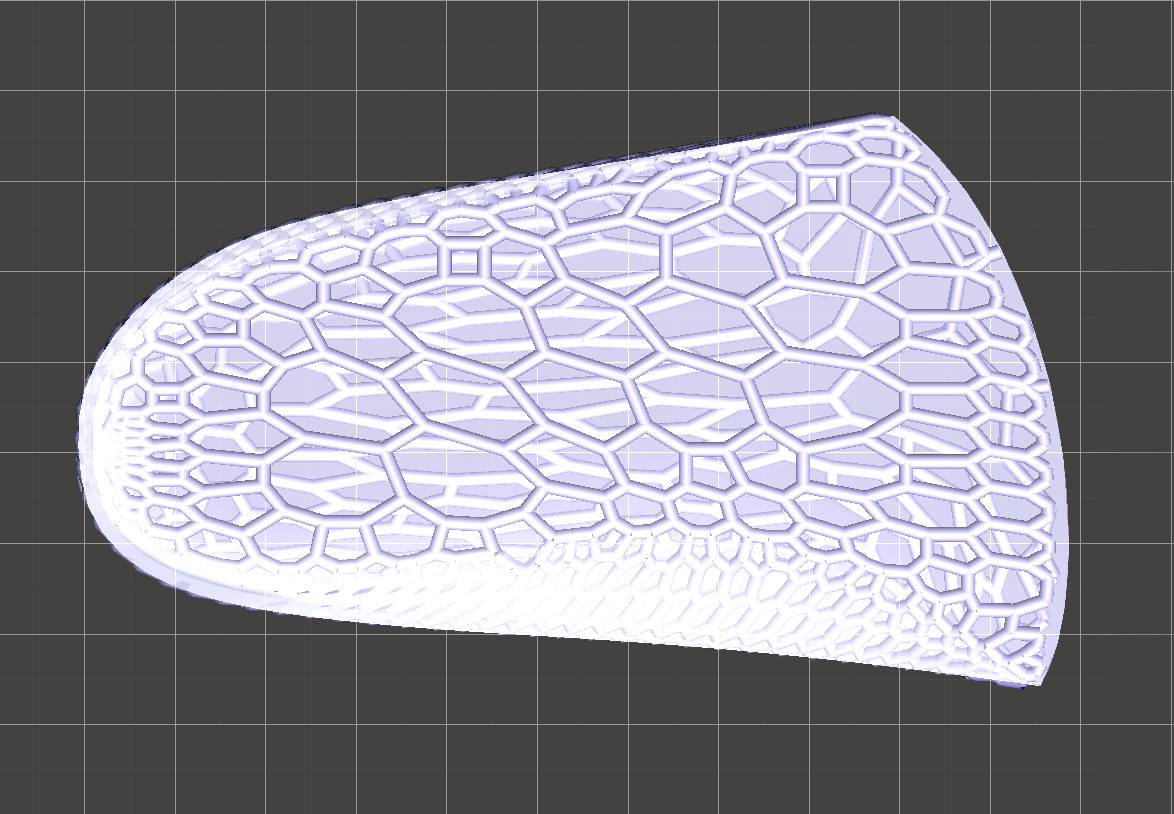

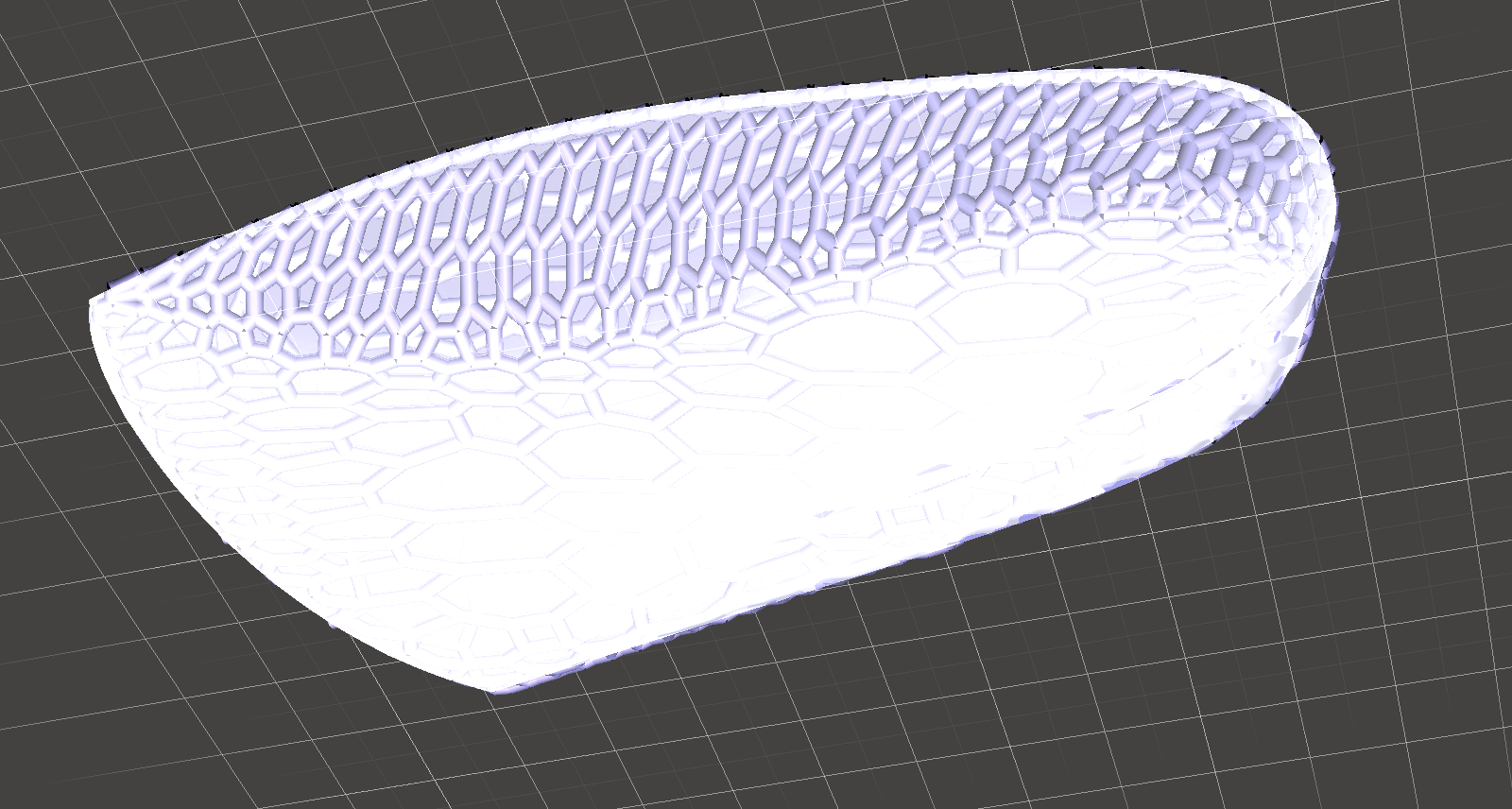

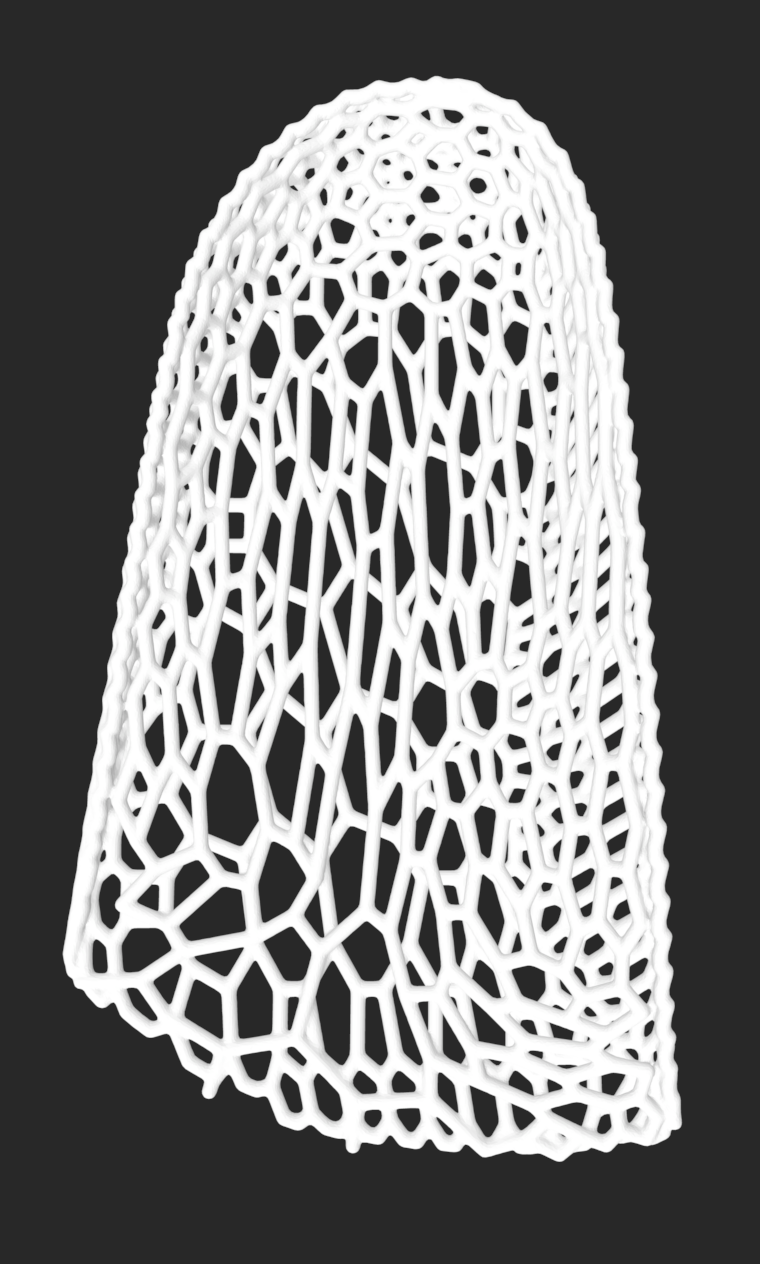

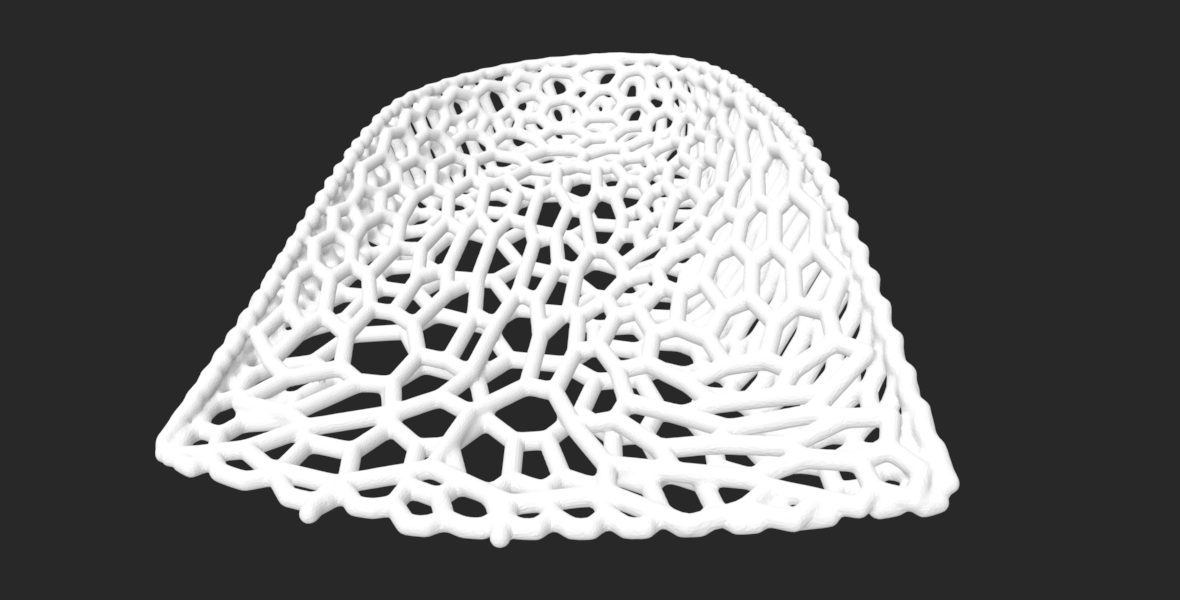

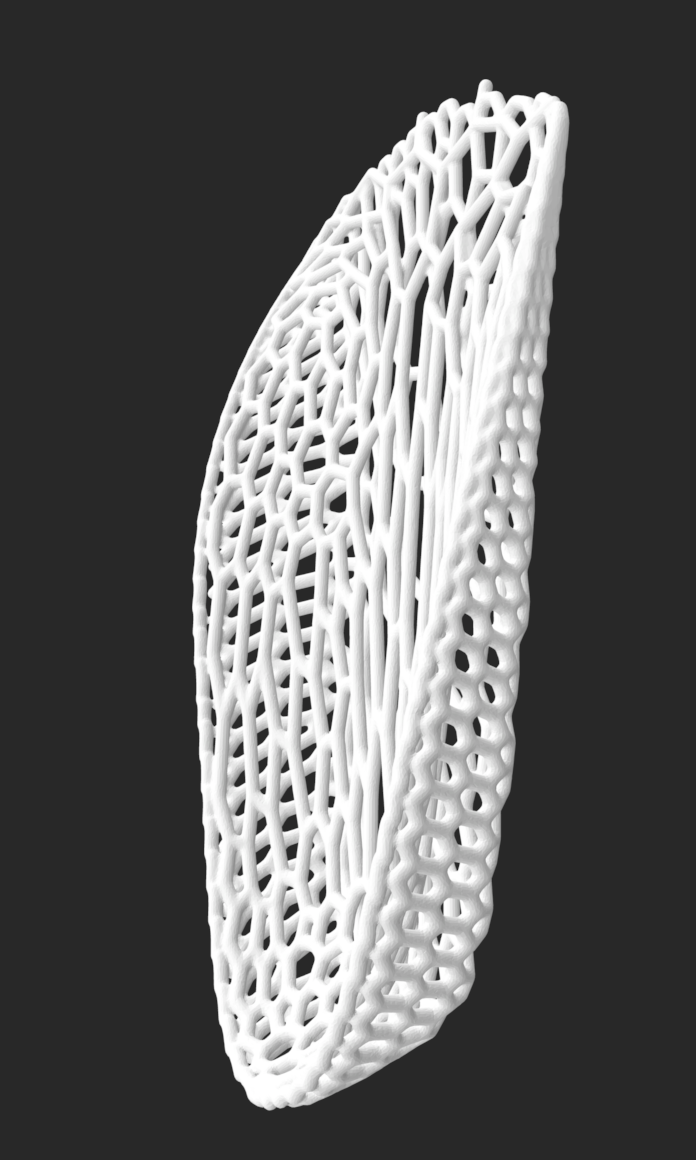

The orthotics industry has been slow to utilize CAD and 3D modeling, so I decided to create a custom insert that my company could use if they wanted to start transitioning into CAD. To create this 3D custom insert, I used Rhino and followed the surface of a foot scan for the shape. Then I added the lattice structure in Meshmixer. This design below is called a Sulcus length insole, which provides a rigid and stable platform to correct a variety of biomechanical issues. The lattice structure would be beneficial in this situation because it creates a lightweight and durable feeling for the patient.

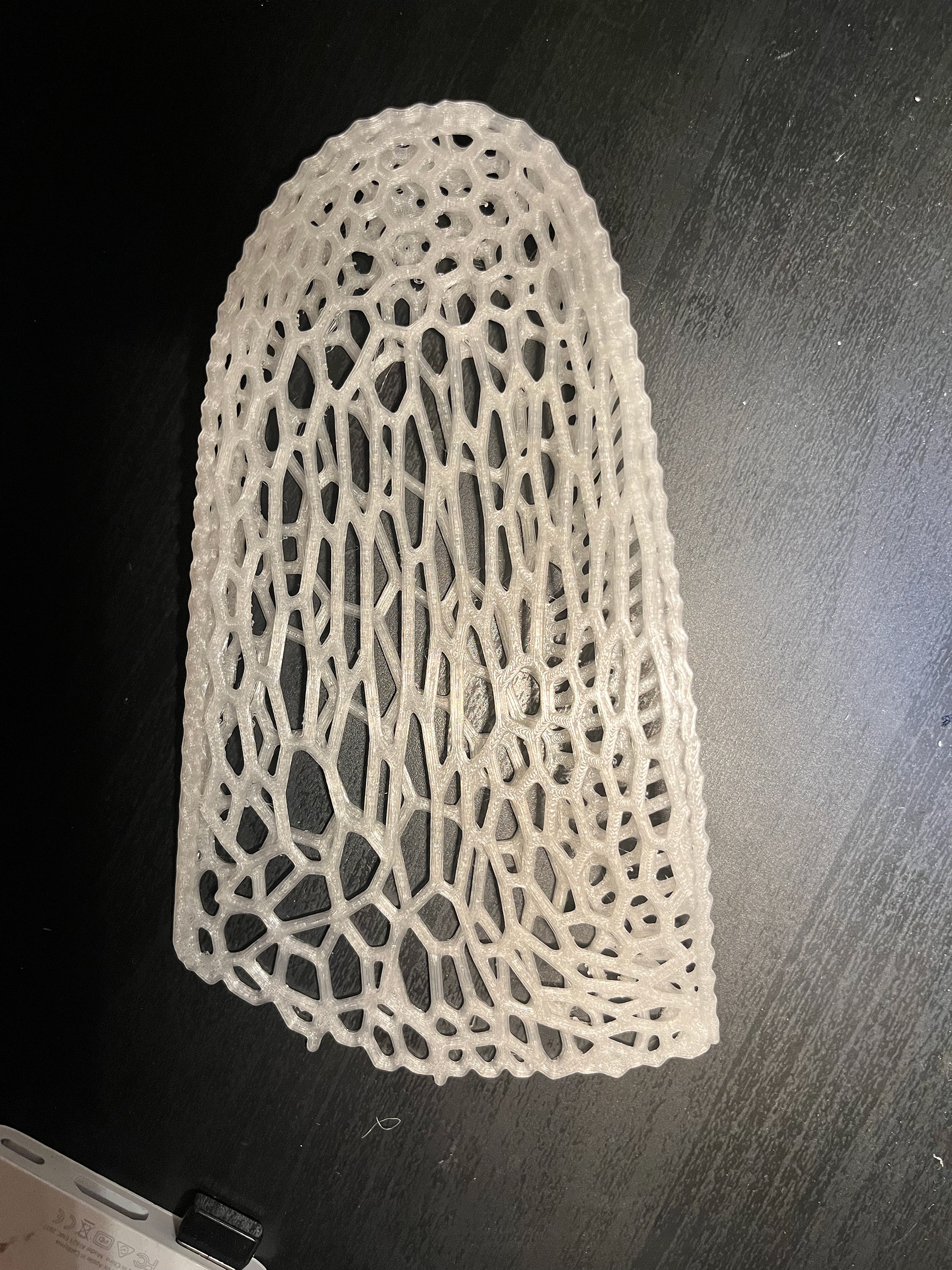

Lattice Insert Iteration #1

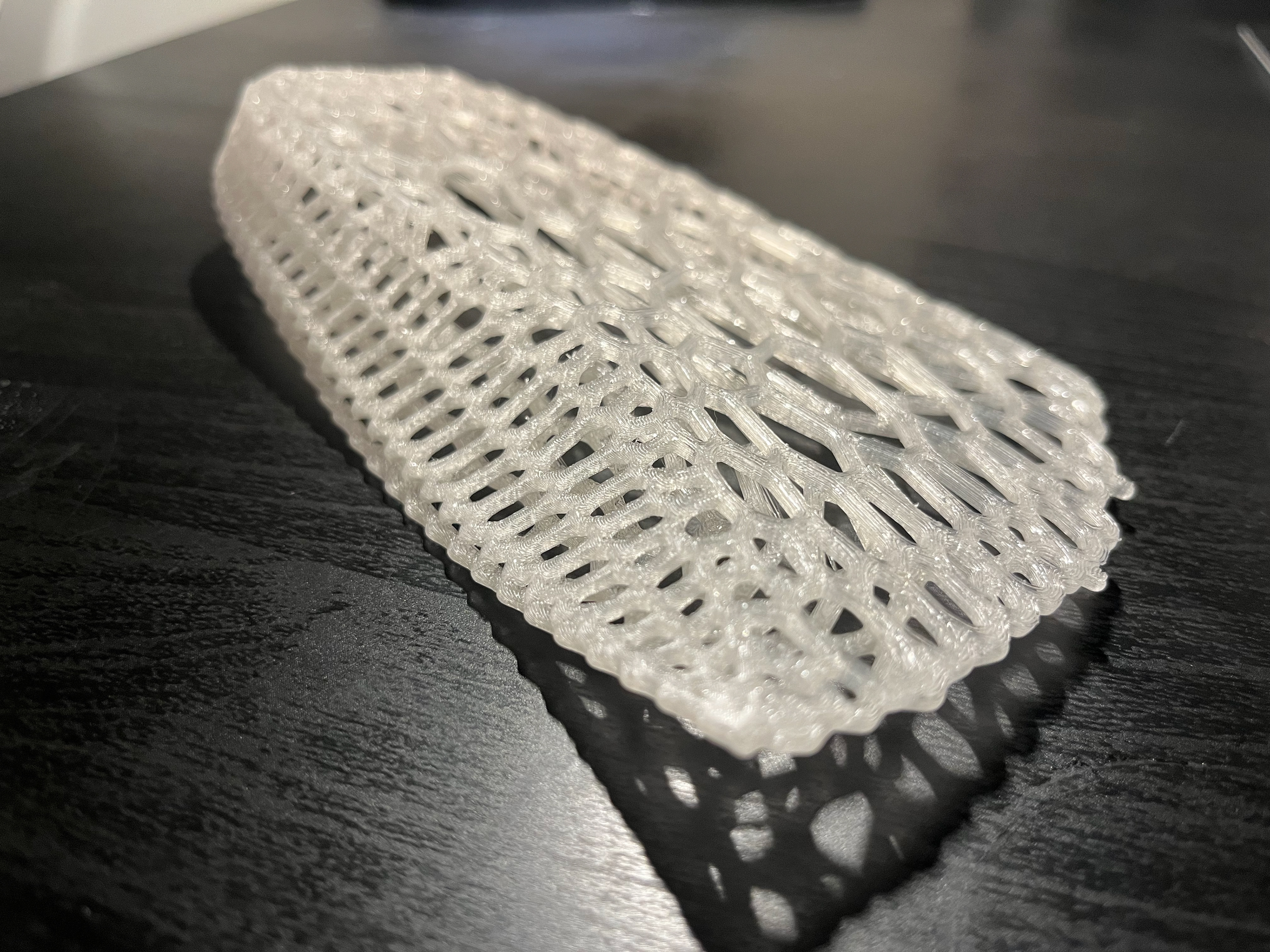

Lattice Insert Iteration #2

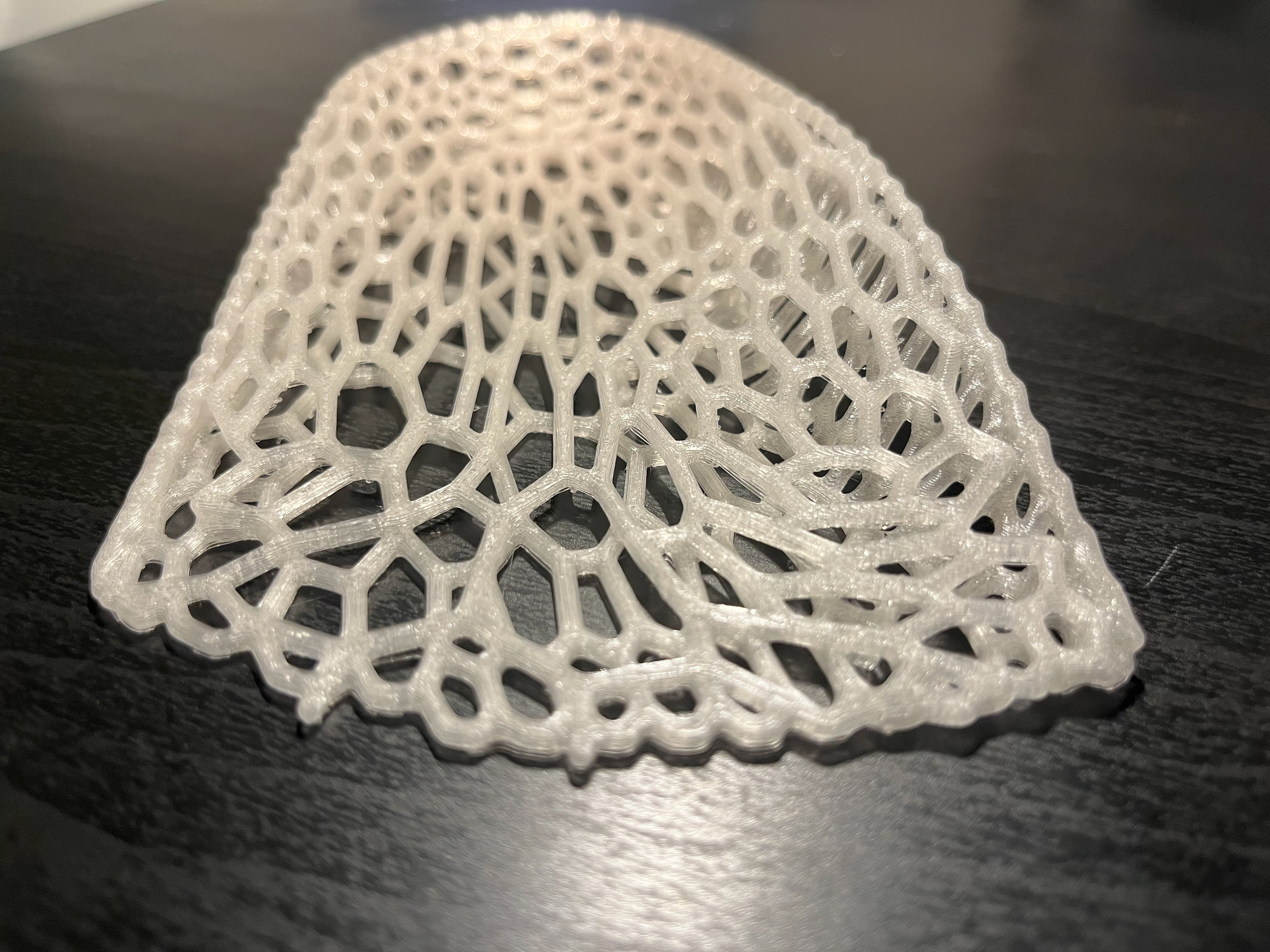

Lattice Insert Iteration #3

Lattice Insert Iteration #4

I considered this iteration the best because of the balanced structures throughout.

3D Print